Shearing machines are essential tools in the manufacturing industry, used to cut metal sheets into desired shapes and sizes. Among the different types of shearing machines, hydraulic and mechanical shearing machines are the most prevalent due to their distinct operational characteristics and advantages. A hydraulic shearing machine operates using hydraulic cylinders to deliver the force necessary for cutting. These machines are known for their ability to exert consistent and adjustable pressure, which is particularly beneficial when dealing with various thicknesses of metal sheets. Mechanical shearing machines, on the other hand, rely on a flywheel that generates energy and delivers the cutting force through mechanical linkages. These machines typically boast faster cutting speeds and are renowned for their reliability and straightforward operation. Selecting the appropriate type of shearing machine is a critical decision for manufacturers, as it can significantly affect operational efficiency, maintenance costs, precision, and the overall quality of the products. This article on comparing hydraulic vs. mechanical shearing machines provides insights into their operational mechanisms, advantages, limitations, and the contexts in which they excel. Let's start. Hydraulic shearing machines leverage hydraulic power to drive the cutting blade. Here's a detailed look at how they function: Hydraulic shearing machines typically require regular maintenance to ensure optimal performance. This includes: While maintenance can be more intensive compared to mechanical machines, hydraulic shearing machines often have longer lifespans and can handle a wider range of materials. Mechanical shearing machines operate using mechanical force, typically through mechanisms such as flywheels and crankshafts. Here's how these machines work: Mechanical shearing machines tend to have lower maintenance requirements: These maintenance tasks are generally less frequent and less costly compared to hydraulic systems, making mechanical shearing machines cost-effective for high-volume production. Hydraulic shearing machines are known for their smooth and controlled cutting action, which ensures high precision. However, this precision results in a slower cutting speed due to the nature of fluid dynamics and the need for fine control. Mechanical Shearing Machines Mechanical shearing machines excel in speed and efficiency. The mechanical force generated by flywheels and crank mechanisms allows for rapid cutting operations, ideal for high-volume production. While speed is crucial, precision and accuracy are equally important factors to consider. Hydraulic shearing machines offer exceptional precision and accuracy, making them ideal for applications where exact measurements are critical. Although mechanical shearing machines are known for their speed, they may not match the precision levels of hydraulic machines due to the rapid movement of mechanical components. Hydraulic shearing machines require regular maintenance to ensure optimal performance and longevity due to the complexity of their systems. Mechanical shearing machines have simpler maintenance requirements but still need attention to ensure continued efficiency. Mechanical shearing machines are not outdated; they continue to be valuable in high-speed, high-volume production environments. While hydraulic models offer advancements in precision and versatility, mechanical shears remain relevant for tasks requiring rapid, efficient cuts on thinner materials. For high-precision cutting, hydraulic shearing machines are typically the preferred choice. The ability to fine-tune the pressure applied during the cutting process allows for greater control over the cut, resulting in more accurate and cleaner edges. Additionally, hydraulic machines often come equipped with advanced features like variable blade gaps and digital readouts, further enhancing their precision capabilities. Mechanical shearing machines, while fast and efficient, may not provide the same level of control required for precise cutting, especially on thinner or more delicate materials. The typical lifespan of both hydraulic and mechanical shearing machines can be quite long if proper maintenance is upheld, often ranging between 10 to 20 years or more. Hydraulic machines, with their complex systems, might necessitate more frequent component replacements and maintenance checks, potentially impacting their longevity if neglected. Mechanical shearing machines, with fewer complex components, generally have a reputation for durable and long-lasting performance. Nonetheless, regular maintenance and adherence to operational guidelines are critical to extending the lifespan of both machine types. Hydraulic and mechanical shearing machines each have unique operational characteristics that make them suitable for different applications. Hydraulic shearing machines utilize hydraulic cylinders to exert cutting force, allowing for consistent and adjustable pressure. This versatility makes them ideal for cutting metals of various thicknesses and for applications requiring precise and clean cuts. In contrast, mechanical shearing machines use a flywheel mechanism to store and release energy, delivering rapid and repetitive cutting actions. They are often favored for their high-speed performance and reliable operational simplicity. Manual Saw Blade Pipe Cutting Machine 1. Servo motor driving feeding system with AC servo motor / C5 level ball guide screw and linear guide rail, fast, stable and accurate. Maximum feeding speed of 1000mm / s and feeding length of 1000m, multiple feed. Pipe Cutting Machine Blade,Manual Pipe Cutting Machine,Manual Saw Pipe Cutting Machine,Pipe Cutting Machine Saw Blade GUANGDONG CHITTAK INTELLIGENT EQUIPMENT CO.,LTD , https://www.nbctkcutting.comI. Introduction

II. Working Principles

Hydraulic Shearing Machines

Maintenance and Costs

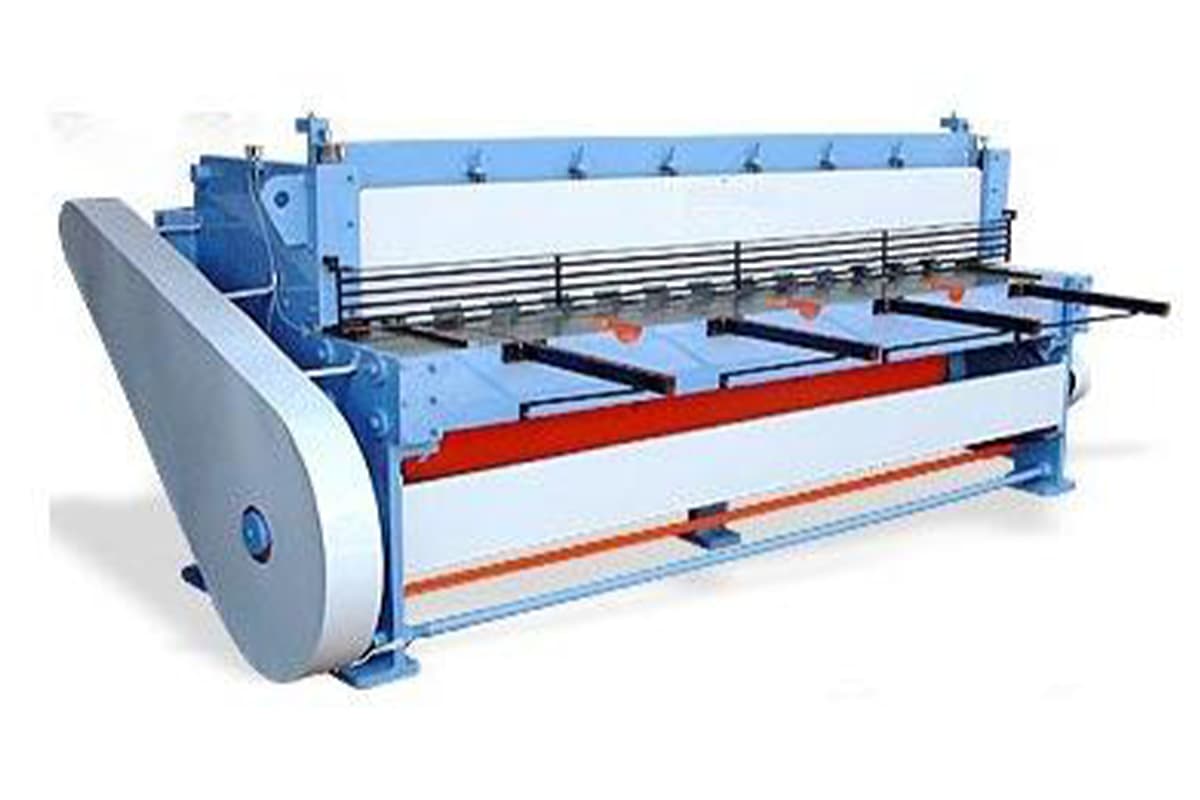

Mechanical Shearing Machines

Maintenance and Costs

Hydraulic vs. Mechanical Shearing Machine Comparison Table

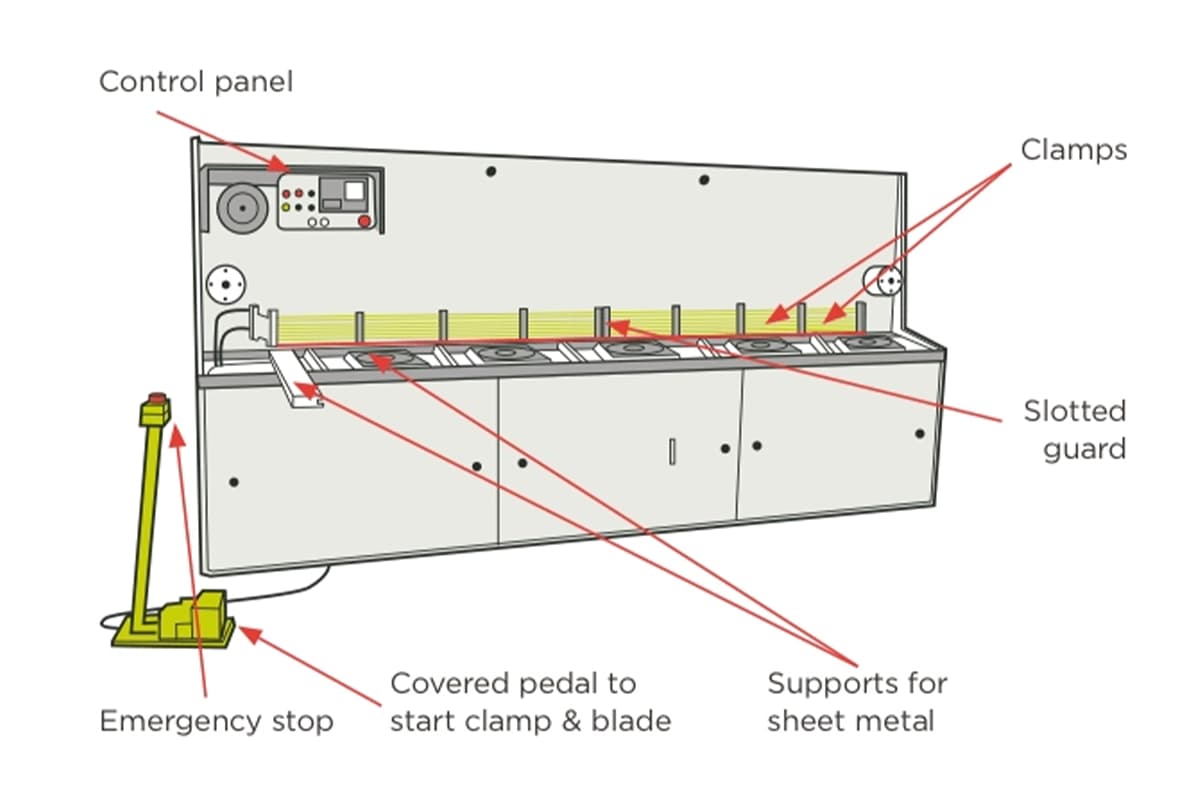

Feature Hydraulic Shearing Machines Mechanical Shearing Machines Working Principle Operate using hydraulic pressure to drive a cutting blade through the material. Utilize a mechanical lever system to exert force on the cutting blade. Force Generation Hydraulic cylinders generate force by pressurizing hydraulic fluid. Mechanical force is generated through a flywheel and clutch system. Blade Movement The blade is drivenbyhydraulic cylinders, allowing for smooth and controlled cutting actions. The blade movement is powered by mechanical components,often resulting in less smooth operation compared to hydraulic systems. Precision and Control Offers high precision and control over cutting force and speed, suitable for various materials Generally less precise than hydraulic machines due to mechanical limitations Types Includes swing beam shears and guillotine shears,each with specific operational characteristics Typically involves simpler designs without the variety seen in hydraulic machines. Precision High precision, suitable for complex cuts Moderate precision, best for straightforward cuts Material Thickness Can handle thicker materials Limited to thinner materials Operation Smooth, consistent operation Faster operation, suitable for high-volume Initial Cost Higher initial investment Lower initial investment Maintenance Requires more frequent maintenance Easier and less frequent maintenance Applications Aerospace, automotive, heavy machinery Metal fabrication, appliance manufacturing, electronics Technological Advancements CNC integration, improved precision Automated blade adjustments, enhanced efficiency Safety Features Advanced safety mechanisms like light curtains Basic safety features, can be enhanced III. Hydraulic vs. Mechanical Shearing Machines Key Components

Hydraulic Shearing Machines

1. Hydraulic System

2. Cutting Blade Assembly

3. Control System

4. Frame and Bed

5. Backgauge

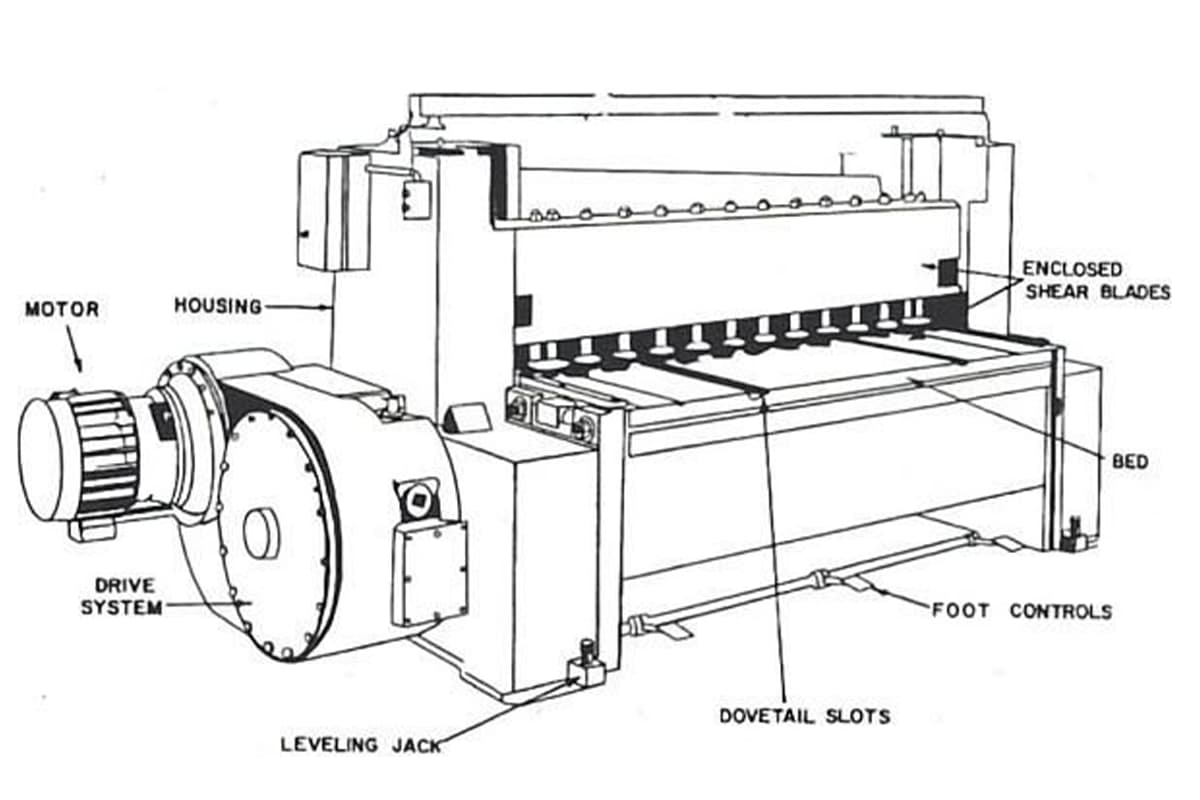

Mechanical Shearing Machines

1. Flywheel

2. Crank Mechanism

3. Cutting Blade Assembly

4. Control System

5. Frame and Bed

6. Backgauge

IV. Hydraulic vs. Mechanical Shearing Machines Performance Comparison

Speed and Efficiency

Hydraulic Shearing Machines

Precision and Accuracy

Hydraulic Shearing Machines

Mechanical Shearing Machines

Maintenance Requirements

Hydraulic Shearing Machines

Mechanical Shearing Machines

V. Hydraulic vs. Mechanical Shearing Machines: Pros and Cons

Pros and Cons of Hydraulic Shearing Machines

Advantages Details Precision and Accuracy Provides smooth, consistent force for precise cuts with minimal distortion. Useful in industries like aerospace and automotive where precision is critical. Ability to Handle Thicker Materials Can cut through thicker and tougher materials, making them ideal for heavy machinery manufacturing and shipbuilding. Smooth and Quiet Operation Reduces vibrations and noise, creating a safer and more comfortable working environment compared to mechanical shears. Versatility Offers adjustable parameters such as blade gaps, cutting angles, and stroke lengths, allowing for use with a variety of materials and thicknesses. Disadvantages Details Higher Initial Cost Requires a significant initial investment due to the advanced hydraulic systems and precise control features. Intensive Maintenance Requirements Needs regular maintenance, including hydraulic fluid replacement and inspection of seals, hoses, and cylinders, which can increase downtime and costs. Slower Cutting Speed Precision comes at the cost of speed, making these machines less suitable for high-volume production environments. Pros and Cons of Mechanical Shearing Machines

Advantages Details High-Speed Operation Rapid cutting speeds enabled by flywheels and crank mechanisms make these machines ideal for high-volume production. Lower Initial Cost Simpler mechanical systems result in a more affordable price, making them accessible to a wide range of businesses. Simpler Maintenance Requires less complex maintenance—regular lubrication, occasional inspections, and blade sharpening keep them running efficiently with minimal downtime. Robust and Reliable Durable and dependable with a straightforward design, suitable for repetitive, long-term, and high-volume cutting tasks. Disadvantages Details Limited Precision High-speed operation can lead to minor distortions or rough edges, especially when cutting thicker materials. Noise and Vibrations Generates significant noise and vibrations, potentially creating a less comfortable working environment. Limited Ability to Handle Thicker Materials More suitable for thinner materials, with limited capacity to cut through thicker and tougher materials compared to hydraulic shears. VI. FAQs

1. Are mechanical shearing machines outdated with the advent of hydraulic models?

2. Which type of shearing machine is more suitable for high-precision cutting?

3. What is the typical lifespan of hydraulic vs. mechanical shearing machines?

4. What are the main differences between hydraulic and mechanical shearing machines?

2. Gearbox driving Saw Blade, is produced by casting and processing by CNC machining center, which is stronger and more accurate. Inside, the core components of gearbox are imported from Taiwan, which produced with advanced milling and vacuum heat-treatment, so they are precise and long lifetime, lower noise and high transmission efficiency. Saw blade can work stable and process in long lifetime.

3.The special designed clamp has strong clamping capacity, firm, safe and reliable.

4. Automatic circulation of coolant ensures smooth cutting surface and long service life of saw blade.

5. Great Clamping device of pipes can decrease pipes vibration during working to extend saw blade lifetime and guarantee feeding speed with the Patent No.ZL 2009 1 0039079.8

6. Servo tail processing device, when the material is more than 100mm left, automatically cut the tail, avoiding that after the former automatic pipe cutting machine has finished cutting, the tail should be cut again separately, saving material and labor and improving production efficiency. Min tail length is 20-30mm.

7. Stop gauge is equipped, that used as keeping alignment of pipes and providing original point for system in order to improve preparing time and avoid the mistake of feeding by manual.

8. Control system is developed by Chittak that is with rich database, and can be updated. Easy operate.

9. It is equipped with an automatic detection and alarm information system, which is convenient for users to troubleshoot.

10.Using Mitsubishi PLC controller, the circuit is simple and the maintenance is simple, response is fast.

11.Can set 5 different cutting lengths for a single material to reduce waste of surplus materials.

12.Length digital display and easy setting and operating in control system.

13.The model can be updated with automatic loading system that can greatly improve efficiency and save the labor cost. Meanwhile, it can be equipped with conveyor belt to transport the finished goods to next machine process. All updated functions can be controlled by Cutting Machine System.