A laser cutting machine is a high-precision and high-efficiency modern manufacturing tool. It utilizes a high-energy-density laser beam as a heat resource to cut the material precisely. This non-contact processing method makes it widely used in various types of metals and the non-metal manufacturing industry owing to its extraordinary precision, flexibility, and adaptability. The laser cutting systems are controlled by computer programs, which can achieve complex two-dimensional and three-dimensional rapid prototyping of geometric shapes, greatly improving production efficiency and product quality. In the laser cutting process, normal cutting usually refers to straight or curved cuts perpendicular to the workpiece surface. However, with the changing of technique advancement and actual needs, laser cutting machine has the function of “cutting an angleâ€. Laser cutters cut angle means cutting the material not at right angles but at an angle. This operation can not only achieve distinctive effects that traditional cutting can not realize but also offers renewed solution plans for structure assembly, welding, and function optimization. A laser cutting machine is a widely used machine that can provide precise cutting. Can laser cutters cut an angle? The answer is yes. A laser cutting machine can cut the material at various angles, achieving intricate designs and precise bevels. Laser cutting is a technique that uses a high-energy-density laser beam to irradiate material surface, making it quickly melt, vaporize or burn, thus achieving precise separation. The whole laser-cutting process can be divided into the following key steps: Focusing and positioning: first of all, the laser generates a high-intensity laser beam and uses optical systems to make it focus into a minimum light spot, precisely aligning the area to be cut. Energy transmission: the laser beam after being focused works on the material surface at extremely high energy intensity, making the area absorb the energy in a very short time, reaching the melting point or even the boiling point. Material removal: with the accumulation of heat, the material starts to melted and vaporize. At the same time, the melt or steam is blown away from the cutting area to form a clear cut via assistant gases (like oxygen, nitrogen). Dynamic fabrication: computer programs controlling the system adjust the position and power of the laser head timely according to the default design path, achieving constant and precise cutting work. Owing to its high precision, flexibility, and widespread adaptability, the laser cutting technology is widely appreciated, and the following are typical materials suitable for laser cutting: Metal materials: including multiple special metals like mild steel, stainless steel, aluminum, copper, and titanium alloy, in which fiber laser cutting machine is skilled at dealing with thin to medium thickness metal sheets. Non-metal material: such as plastic, rubber, wood, paper, glass, ceramics, leather, textiles, etc. The CO2 laser cutting machine features good cutting effects in handling non-metal materials. Composite material: including carbon fiber composites, glass fiber reinforced plastics (GFRP), and other types of composite panels. Efficient cutting can also be achieved with the help of specific parameter settings. Strengthening structure intensity and stability: for some engineering structural parts like aircraft parts, bridge connectors, joints formed by angle cutting disperse stress, improve stability and fatigue resistance of the overall structure. Simplify the assembly process: by pre-cutting parts at angles, the needs of subsequent assembly can be precisely matched, and welding and adjusting works, when assembled, can be reduced, improving assembly efficiency and accuracy. Save the material and optimize the design: angle cutting can better adapt to geometric shape design needs. Meanwhile, by rationally utilizing the remaining materials, the material waste can be reduced and resource utilization can be improved. Artistic beauty and personalized expression: in the sphere of decorating artistic and building components, angle cutting can create distinctive visual effects, enrich the design level, and achieve personalized and innovative design. Aerospace industry: in aircraft manufacturing, mass oblique joint designs are required to strengthen the rigidity of the body structure and relieve the weight, in which angle cutting plays a pivotal role. Automotive manufacturing: many components like body structural parts, interior parts and engine parts need precise angle cutting to ensure tight fit and efficient production between the components. Achitechive industry: complex node connectors in steel structures require angle cutting to meet the mechanical performance requirements and aesthetics. Furniture manufacturing: creative furniture design usually requires an angle-cutting process, making the product appearance unique, and structure stable. Electronic and precision instrument manufacturing: small and delicate metal shells and internal brackets can improve the packaging density and thermal performance via angle cutting. Different materials have different properties. This may affect the effect laser cutting machine cuts an angle. For example, a material with a high melted point or reflective surface may bring about challenges when cut at an angle. It is essential to know the materials being used and their properties to ensure compatibility with laser-cutting machines. The thickness of the material being cut is paramount for a laser-cutting machine to cut an angle effectively. Thicker material may need larger power and slower cutting speed to achieve clean and precise cutting. Please refer to the specification and guidebook of the laser cutting machine, to ensure it can handle the largest thickness with an angle. The divergence of the laser beam during propagation is also a key factor. The more concentrated the laser beam, the smaller the diameter of the focused spot, and the higher the energy density. This may be beneficial for precise angle cutting. However, the laser beam may diverge, causing focus points to offset when cutting at a large angle, affecting the cutting precision and efficiency. The choice and adjustment of lens focal length is essential for achieving high-quality angle cutting. In laser cutting machine, the lens focal length can be adjusted to control the location and depth of the laser point, thus changing the energy distribution the laser works on material surface. In order to keep best energy density and cutting effects during the angle cutting, the lens focal length can be adjusted dynamically according to actual cutting angle. Bevel cutting is adjusting the angle and focal length of the laser head to make a laser beam work on the material surface at an angle, achieving workpiece edge ramp cutting. This technique is widely used in many spheres like tubes, welded joints, and frame structures because it can pre-create ideal welded angles for parts, which improves welding quality and efficiency. Tilt-cutting technology means setting the workbench or laser head at a specific angle instead of directly vertically to the workpiece surface during laser cuts. This method generates cuts with different angles in a single operating step, which is especially suitable for component manufacturing requiring precise angle equipment. This method can reduce the following processing procedures, and improve production efficiency, especially for some specific design products, like architectural decorative parts, and furniture components, which can achieve multiple-angle designs. In some high-end laser cutting systems, rotational cutting technology is adopted. Under this circumstance, the laser cutting head can not only move along the X-Y axis but also around the Z-axis, thus changing the laser beam incident angle during the cutting process. This rotation cutting technology is especially suitable for producing intricate three-dimensional geometrical shape components, such as aviation blades, turbine parts, and art engravings, which can flexibly handle the cutting needs of various angles and curved lines. When cutting an angle, especially for handling thicker or heat sensitive materials, the high temperature generated by the laser beam may lead to uneven heat on parts of the workpiece, causing thermal deformation. This heat-affected zone may decrease the precision of the cutting edge. produce slag, burrs, or internal stress changes in the metal because of over-heat, affecting the final product quality. As for some thin sheet metals or other materials easily deformed by heat, the accumulated heat during angle cutting may cause the whole workpiece to warp or twist. The cooling shrinkage process of materials probably leads to irreversible shape change under the circumstance of large angles and deep incisions, increasing the difficulty of following fabrication and equipment. Dynamic focus and power control: adjust the location of the laser focus point and input power timely, ensuring the energy is distributed evenly, decreasing the heat-affected zone, and lowering the risk of low heat deformation. Optimization of assistant gas: using proper assistant gases (like nitrogen, and oxygen) to enhance the blowing effect on molten material, accelerate the cooling process, and reduce warpage. Multiple-axis linkage technology: a laser cutting machine with multi-axis linkage is adopted to adjust the angle and location of the laser head more flexibly, achieving more complex precise angle cutting, and better controlling the heat input, and avoiding workpiece deformation. Pre-cooling and post-treatment process: pre-cooling the workpiece or rapid cooling process after cutting, which is beneficial to control the temperature of the workpiece, and decrease the occurrence of heat distortion. In a nutshell, featuring its prominent advantages, laser cuts at an angle play an increasingly important role in modern manufacturing. In our passage, we talk about the precision and accuracy of angle-cutting. This technology can achieve high precision and high-quality angle-cutting, which can greatly meet the complex angle-cutting requirements for aerospace, automotive manufacturing, and other precision components. Compared with the traditional cutting method, laser cutting at an angle performs well in time and cost. Automatic control and high-efficiency fabrication processing can effectively decrease production costs and improve overall efficiency. Meanwhile, reducing material waste is also a prominent advantage, which can maximize resources and sustainable production advancement. What’s more, even laser cutters at an angle are faced with heat deformation and material warping. With technology innovation and crafts improvement, such as dynamic focusing, intelligent control systems, and the development of composite processing technology, these problems are being solved, increasingly expanding the laser angle cutting application scope and capacity limit. If you want to learn more about the laser cutting machine, please visit our official website or contact our salesman for details. Titanium T Bars,Scooter T Bars,Black Titanium Scooter Bars,Titanium Bars Scooter Bao Ji Titour Technology Co.,Ltd , https://www.cntitour.comI. Introduction

Brief overview of laser cutters

Introduction to cutting at an angle

II. Understanding Laser Cutting

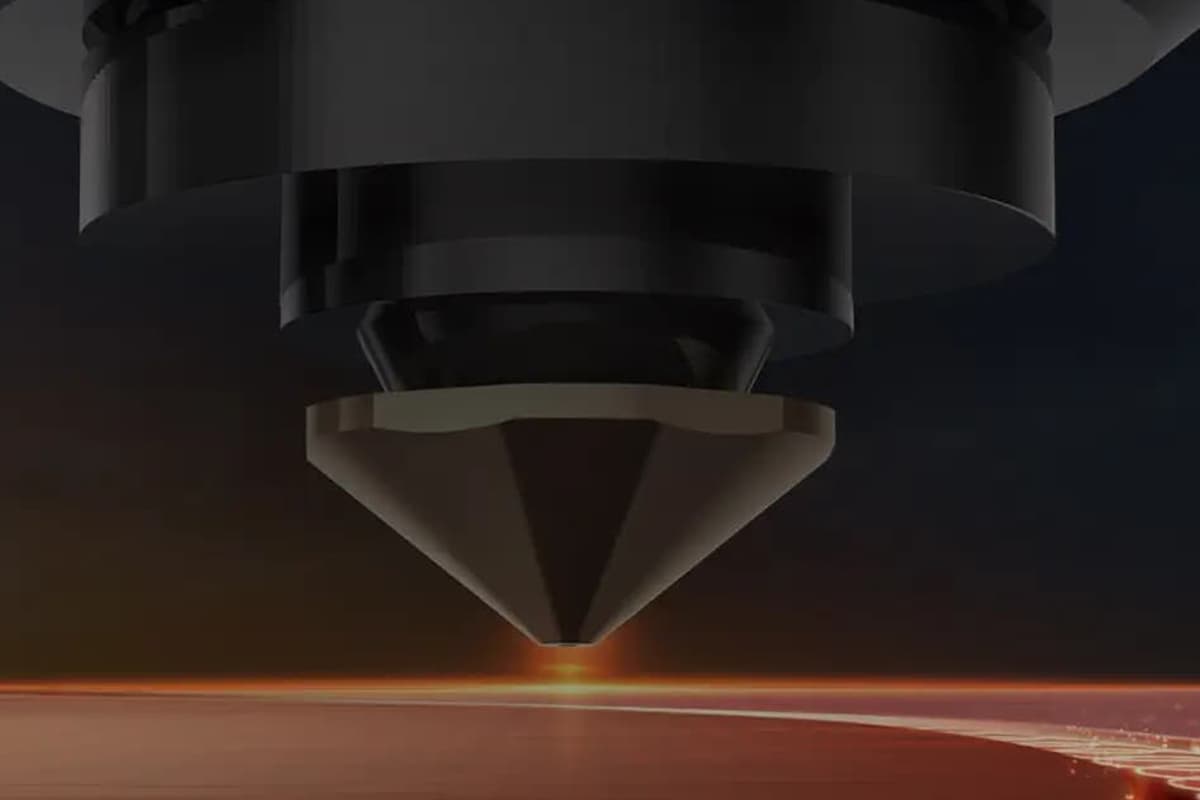

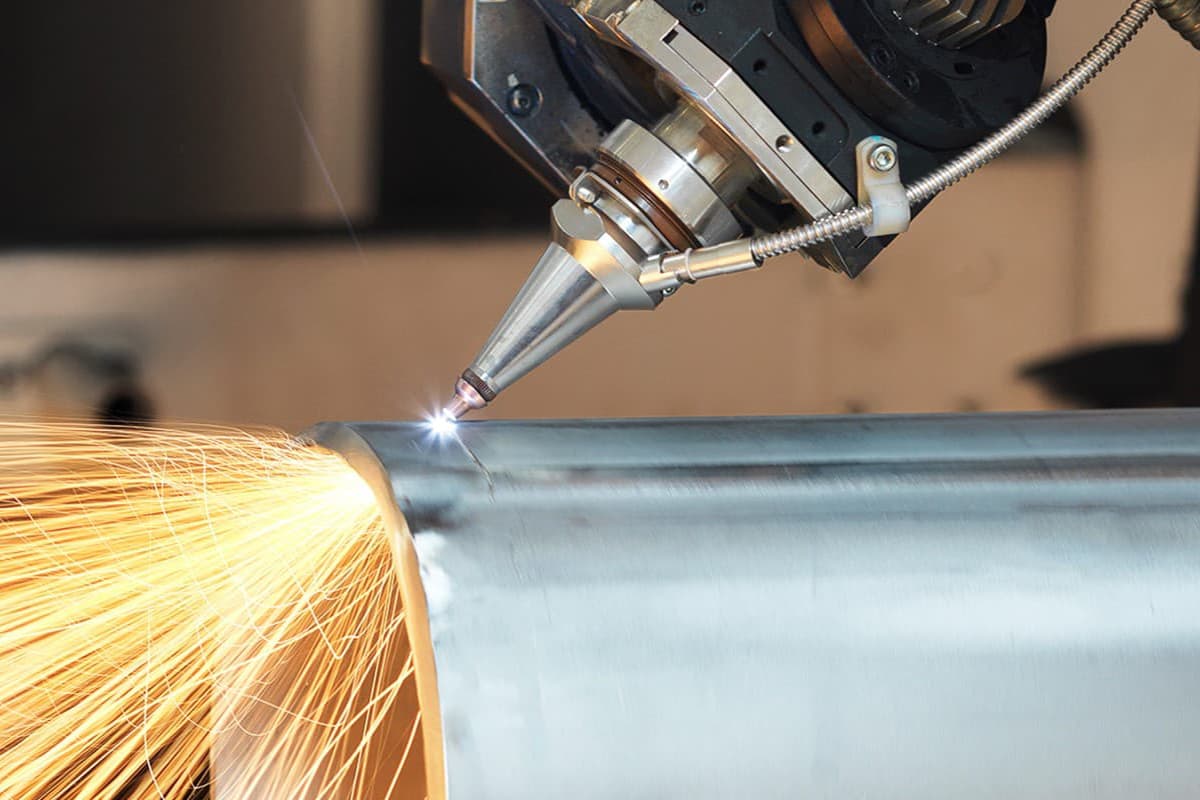

Explanation of laser cutting process

Types of materials suitable for laser cutting

III. Angle Cutting with Laser Cutters

Benefits of cutting at an angle

Applications of angle cutting in various industries

IV. Factors Influencing Angle Cutting

Material considerations

Thickness limitations

Beam divergence

Lens focus

V. Techniques for Cutting at an Angle

Bevel cutting with laser technology

Tilt Cutting Methods

Rotational Cutting Approaches

VI. Challenges of Angle Cutting

Heat distortion issues

Material warping concerns

Overcoming limitations in angle cutting

VII. Conclusion