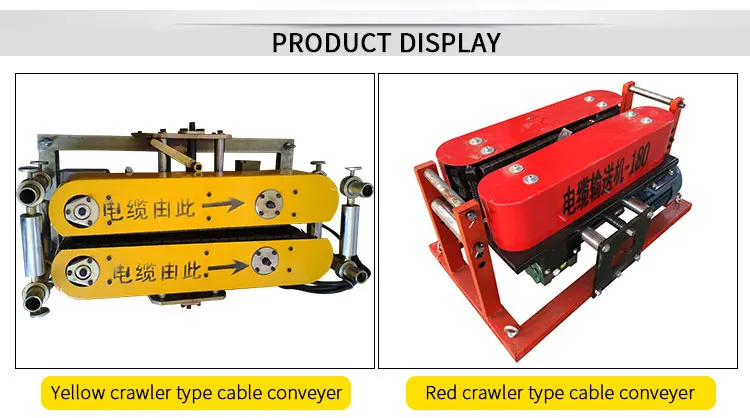

Cable conveyer details:

Usages

DSJ series product is an electric machine for laying power cables (or communication cables).

Packing

Cable conveyer be packed in cartons or pallet.

Applications

Cable conveyer applied in Long distance cable laying.Small volume, light weight, easy to operate.

Features:

1. The two vertical shafts drive the transmission force and gravity respectively in two directions of the cable to protect the insulation of the cable.

2. The transmission force is transmitted through the compound caterpillar, and cater pillar adopts high strength wear-resisting rubber, which make the power force uniform and durable.

3. The machine is equipped with adjustable roller, which is very convenient.

4. The upper part of the machine can be fitted with a hinge wheel, which can be used for small power traction.

5. The machine has low mechanical noise, small temperature rise and easy maintenance.

6. Support products can be provided by user, like –DSJ series electrical control system (total control box, control box) and winding wheel etc.

Data sheet of Cable conveyer:

Cable Conveyer,High Strength Cable Conveyer,Electric Cable Conveyer,Cable Conveying Machine Hebei Long Zhuo Trade Co., Ltd. , https://www.hblongzhuo.com

Not long ago, with the first batch of 50 heavy-duty engines smoothly off the assembly line, it was announced that the current domestic heavy-duty diesel engine test line with world advanced level was officially put into operation in Guangxi Yuchai.

The heavy-duty diesel engine test line with an investment of 220 million yuan has an area of ​​more than 16,000 square meters. It costs only 140 million yuan to import equipment. The major equipment is imported from Europe. The production line has extensively used online measurement, online collection, dynamic information management system, PMS (production management system), QDM (quality management), and PMS system to realize the entire process monitoring from production to production.

This test line innovatively uses a number of advanced process designs, introduces four advanced assembly lines from Germany, uses the current world's popular internal and external assembly lines, and is equipped with advanced on-line inspection, semi-automatic assembly equipment, quality and production management systems, and adopts advanced semi-finished product spray paints. The process, ABB robot automatic spray paint, not only to improve the working environment of the operator, but also to improve the appearance of the product quality; AGV car for the first time the introduction of transport, to improve safety and save equipment space, but also greatly improve the transport efficiency. The pre-assembly line of the trial machine bears the installation and inspection of related tooling and auxiliary parts before the test machine, realizes centralized management, reduces the auxiliary time of the gantry crane, and improves the utilization rate of the gantry up to 30%.

In addition, in every post of the assembly, the system automatically presents the station information, such as the online detection of the protruding height of the cylinder sleeve, the accurate positioning and measurement of the crankshaft, the automatic reversal, the automatic camshaft, the automatic tightening, and the on-line measurement integration. The stability of parts and quality is controlled. The automatic and semi-automatic degree of the entire production line has reached more than 50%, which will greatly reduce the labor intensity of workers and increase production efficiency. It is currently the most advanced heavy-duty diesel engine test production line in China. Its successful production has accelerated Yuchai's determination to lead the development of heavy machinery and is a new growth point for Yuchai to accelerate its development.

Model

Advance speed

Range of use

Conveying force

Dead weight

DSJ(G)-150

10.4

Φ60-150

5.5

120KG

DSJ(L)-150

7

Φ60-150

3.8

135KG

DSJ(L)-180

7

Φ60-180

5

160KG